1. Flexible Curtain and Collision Absorption The Anti-Crash Replay Industrial Fast Door is designed with a flexible curtain or panel that acts as the ...

READ MOREIndustrial Sectional Door Manufacturers

-

Anti-Crash Replay Industrial Fast Door

The manual reset method of the Anti-crash Replay Fast Door requires the user to ... -

SD01 Heat Preservation Industrial Sectional Door

Fast opening speed, beautiful and generous, Used efficiently in the logistics fi... -

SD02 Large Span Insulation Industrial Sectional Door

Large-span thermal insulation sectional door is designed for large door openings... -

SD03 Aluminum Single Panel Industrial Sectional Door

It is equipped with safety devices such as wire rope breakage protection devices... -

SD04 Cold Storage Insulation Industrial Sectional Door

This product has good sealing properties and is mainly used in cold chain logist... -

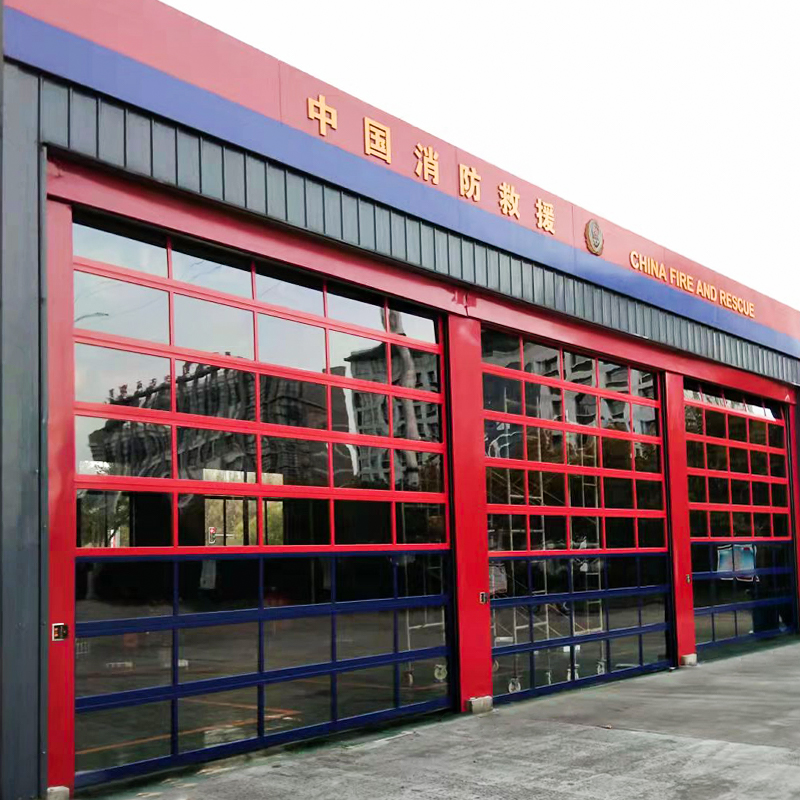

SD05 Fully Transparent Industrial Sectional Door

The aluminum alloy profile frame + double-layer transparent window is solid and ...

An industrial sectional door is a common type of industrial door that is widely used in various industrial and commercial places. It is often used in warehousing and logistics centers, manufacturing, refrigerated and frozen warehouses, automobile repair and service centers, etc.

Industrial sectional door has the following main advantages. First, fast switching operations are performed to improve the efficiency of cargo loading, unloading, and transportation, while reducing waiting time and improving overall logistics and production efficiency. Second, it can provide good thermal insulation and thermal insulation effects, and maintain the stability of the internal environment, while preventing dust, pollutants, and noise from entering, ensuring a clean and quiet working environment. Third, it uses sturdy materials and locking devices to prevent unauthorized entry and improve security. Finally, because of its use of high-strength materials and advanced manufacturing processes, it is durable and has low maintenance costs, providing long-term reliable performance and greatly reducing the frequency of repairs and replacements.

industrial door manufacturer?

We understand that each customer's needs are unique, so we offer customization capabilities to design and manufacture to our customers' specifications. Whether it's special dimensions, specific materials or special functional requirements, we can meet our customers' needs.

FAQ's

Q. What is an industrial door?

An industrial door is a large door specifically designed for industrial use, such as in warehouses, factories, and garages. They are typically characterized by high strength, durability, and safety to meet the demands of frequent operation.

Q. What types of industrial doors are available?

The main types of industrial doors include:

Roll-Up Doors: Made of metal or plastic materials, they save space when rolled up and are suitable for various industrial environments.

Sliding Doors: Slide along a track and are suitable for wide openings.

Folding Doors: Consists of multiple panels that fold when opened, saving space and suitable for large openings.

Sectional Doors: Lift vertically and are ideal for high-frequency use areas like logistics centers and warehouses.Q. How do I choose the right industrial door?

When choosing an industrial door, consider the following factors:

Frequency of Use: Doors in high-traffic areas should be highly durable.

Safety: Ensure the door has necessary safety features, such as anti-pinch, anti-fall devices, etc.

Insulation: For areas requiring temperature control, choose doors with good insulation properties.

Space Constraints: Choose a door type that fits the available installation space.Q. How do I maintain an industrial door?

Regular maintenance can extend the lifespan of your industrial door. Key maintenance steps include:

Regular Inspections: Check for wear and tear on the door, track, and accessories to ensure normal operation.

Lubrication: Lubricate moving parts to ensure smooth operation.

Cleaning: Regularly clean the door and track to prevent debris buildup.

Professional Maintenance: Schedule comprehensive inspections and maintenance by professionals periodically.Q. What safety features should an industrial door have?

Industrial doors should have the following safety features:

Anti-Pinch Devices: To prevent injuries from door closure.

Emergency Stop Button: Allows immediate halting of door operation in emergencies.

Safety Sensors: Detect obstacles under or around the door to prevent accidents.

Automatic Locking: Ensures the door locks automatically when closed, preventing unauthorized entry.Q. What are the common issues with industrial doors and how to address them?

Common issues include:

Door Deformation: Regularly inspect and replace damaged parts promptly.

Unresponsive Operation: Check the control system and power supply to ensure normal function.

Excessive Noise: Lubricate moving parts to reduce friction noise.

Door Jamming: Inspect the track and door, remove debris, and make necessary adjustments.Q. Can industrial doors be customized?

Yes, industrial doors can be customized to meet specific requirements, including size, color, material, and features. Contact the supplier to discuss your specific needs.

Q. What certifications should an industrial door have?

Ensure your industrial door meets industry standards and safety certifications such as ISO, CE, etc., to guarantee product quality and safety.

Q. How do I request a quote or place an order for an industrial door?

You can request a quote or place an order by contacting our sales team via email, phone, or through our website. Provide details about your requirements, and our team will offer suitable solutions and quotes.

Q. Who can I contact for further assistance?

For further assistance or any inquiries, please contact our customer service team. We are here to provide you with professional consultation and support.

Dongtai Geajie Intelligent Equipment Co., Ltd.

-

10+

Years Industry Experience

-

23500+

Factory Area

-

1000+

Project cases

As China Industrial Sectional Door Manufacturers and Industrial Sectional Door Suppliers, Dongtai Geajie Intelligent Equipment Co., Ltd. was Founded in 2014, the headquarters is located in Shanghai, the world's economic center city, and the production base is located in Dongtai City, Yancheng, Jiangsu Province. The company has a modern factory covering an area of 23,500 square meters. "GEAJIE" focuses on automatic door systems, logistics loading and unloading equipment and other product fields. Premium provider of automation solutions for the efficient movement of goods and people. The products cover sliding doors, rapid doors, garage doors, rolling shutter doors, cold storage doors, loading and unloading platforms, door seals, truck restraints, industrial fans, safety facilities and other products. We are committed to satisfying customers' personal safety, property safety, Provide high-quality solutions to meet the needs of convenient operation and energy saving.

GEAJIE introduces European quality standards into our product design and manufacturing processes to ensure continued high quality and to keep the quality and performance of our products at the industry level. We have successively developed industrial categories and logistics equipment that satisfy different industries. Our products are widely used in logistics and warehousing, manufacturing, food and medicine, precision electronics, cold chain logistics, aircraft hangars, ships and other industries.

The company has an outstanding fully automatic continuous production line for industrial door panels, a high-quality loading and unloading platform fully automatic spraying and baking production line, fully automatic welding machines and equipment imported from Japan, high-precision laser cutting machines imported from Germany, various molding equipment, etc. . The comprehensive use of advanced equipment, the combination of automation and specialization, and efficient and collaborative production methods have greatly improved production efficiency. GEAJIE now has an annual production capacity of more than 6,000 various types of industrial doors and 15,000 sets of logistics equipment, able to meet A full range of product solution needs including logistics real estate warehouse development and cold chain logistics warehouse development.

Since its establishment, the company has actively explored the international market and accumulated rich experience in operating foreign projects. GEAJIE has established strategic cooperation with world-renowned companies in multiple industries such as logistics and manufacturing. We have always been committed to stable performance and efficient services, and has received high recognition and positive feedback from global customers for its professional pre-sales consultation, reliable product quality and attentive after-sales service... Our cooperative customers include NetEase, DuPont Chemical, Sinotrans, Shanghai Biopharmaceuticals, and 3Trees , Kaidi Electric, Philips Medical, China Aerospace, Customs Logistics, Chang'an Minsheng Logistics, Shuijingfang, Cargill, Michelin Tires...etc. At present, the company has established a complete global sales network and has service networks in ASEAN, India, Australia and all over the country, providing a strong guarantee for after-sales service.

-

-

Load Capacity VerificationBefore using EOM Industrial Dock Levelers with heavy machinery or oversized pallets, it is essential to verify that the dock...

READ MORE -

How does the Anti-Crash Replay Industrial Fast Door reduce downtime caused by accidental collisions?

Flexible or Break-Away Door Design The Anti-Crash Replay Industrial Fast Door is specifically engineered with flexible and break-away door panels, con...

READ MORE -

Effective Barrier Against Drafts and Air Leaks In industrial environments, large doors are often necessary for machinery, equipment, and vehicle acces...

READ MORE

Industrial sectional door production equipment and process

In modern industrial production, industrial sectional doors are key facilities and are widely used in logistics, warehousing, manufacturing and other fields. In order to meet the market's growing demand for high-quality and high-efficiency products, Geajie Intelligent Equipment has carried out comprehensive technical upgrades and optimizations on the production equipment and processes of industrial sectional doors.

Fully automatic continuous production line

GEAJIE has introduced an advanced fully automatic continuous production line dedicated to the manufacture of industrial door panels. The implementation of this production line has significantly improved production efficiency and ensured product consistency and stability. The fully automated production process effectively reduces manual intervention and reduces the risk of human error, thereby improving the product's qualified rate and ensuring high customer satisfaction.

Automated control system

Our fully automatic production line is equipped with an advanced automated control system that can monitor key parameters such as temperature, pressure and speed in real time during the production process. Intelligent management methods not only improve production efficiency, but also respond quickly to emergencies to ensure the continuity and safety of production. The application of this system represents an important step in the transformation of industrial production to intelligence and digitalization.

Production line layout

The production line layout has been carefully designed and rationally partitioned according to the process flow to ensure efficient connection of each link. From the input, processing, assembly of raw materials to the output of finished products, the entire process is carried out in a closed environment, effectively avoiding the impact of the external environment on product quality. This optimized layout design promotes the improvement of production efficiency and reduces unnecessary time waste.

High-precision laser cutting technology

In the manufacturing process of industrial sectional doors, the cutting link is crucial. GEAJIE uses a high-precision laser cutting machine imported from Germany, which can accurately cut a variety of materials. The application of laser cutting technology ensures that the cutting accuracy reaches the millimeter level, significantly improves the utilization rate of materials, and ensures the rigor and aesthetics of the door structure.

Material adaptability

Our laser cutting machine has a wide range of material adaptability and can handle a variety of materials including steel, stainless steel and aluminum alloy. This diverse material selection enables our industrial sectional doors to meet the specific needs of different customers and show good market adaptability.

Fully automatic spraying and baking production line

In order to ensure the corrosion resistance and aesthetics of the surface of industrial sectional doors, GEAJIE introduced a fully automatic spraying and baking production line. The production line uses advanced spraying technology to achieve uniform and detailed spraying effects, ensuring the stable performance of the product in various environments.

Spraying process

During the spraying process, we use advanced electrostatic spraying technology to significantly improve the adhesion and uniformity of the coating. The coatings used have been strictly screened and have excellent weather resistance and UV resistance, ensuring that the product can still maintain good appearance and performance in a changing environment.

Baking process

After the spraying is completed, the product will enter the baking stage. High-temperature baking not only accelerates the curing process of the coating, but also improves the hardness and wear resistance of the coating. The baking temperature and time are precisely calculated to ensure the best coating effect, thereby extending the service life of the product.

Safety of industrial sectional door

In today's industrial environment, industrial sectional doors not only exist as entrances and exits, but also play a vital role in ensuring safety, improving efficiency and protecting assets. GEAJIE focuses on the research and development and production of high-quality industrial sectional doors, with special emphasis on product safety and reliability.

Safety of structural design

Application of high-strength materials

GEAJIE's industrial sectional doors are made of high-strength steel, stainless steel and aluminum alloy and other high-quality materials. These materials not only have excellent durability and impact resistance, but also can effectively resist external physical damage. The selection of high-strength materials enables the door body to withstand heavy impact and extreme weather conditions, thus ensuring safety in various complex environments.

Structural stability

The structural design after rigorous engineering calculation ensures the stability of the industrial sectional door during opening and closing. The segmented design of the door body allows each part to withstand pressure independently, thereby effectively reducing the stress concentration of the overall structure. This design concept significantly reduces the risk of deformation or breakage during use and improves the overall reliability of the product.

Intelligent safety function

Integration of safety sensors

GEAJIE's industrial sectional doors are equipped with a variety of advanced safety sensors, including photoelectric sensors and pressure sensors. These sensors can monitor the movement of the door body in real time to prevent people or objects from being clamped during the closing process. For example, when the sensor detects an obstacle, the door body will automatically stop or open in the opposite direction to ensure that the safety of people and goods is not threatened.

Anti-pinch function design

Our industrial sectional doors also have an anti-pinch device that can automatically detect any obstacles during the closing process of the door body and stop closing immediately. This function is particularly important in busy logistics and warehousing environments, effectively preventing accidental injuries caused by the closing of the door body and improving operational safety.

Operational safety

Advantages of user-friendly operation interface

GEAJIE's industrial sectional doors are equipped with an intuitive and easy-to-use operation interface, allowing users to easily master the operation mode, whether manual or automatic control. In addition, the operation interface is equipped with an emergency stop button, which is convenient for quickly stopping the operation of the door in an emergency, further ensuring the safety of personnel.

English

English Español

Español Tiếng Việt

Tiếng Việt